Major Partner/Supplier Website, Re:

Annual Operating Expense based on the design capacity (ball park figure)

- 1. electricity

- - 4 pcs of 2hp transfer Pumps, 2 units as standby pumps and 2 units as duty pumps.

- = 1hp is approximately 750 Watts. :, 750 x 2 hp = 1, 500 watts x 2 units (in and out transfter pumps) of 2 Hp = 300 watts. x Per Kilo watts per hour, (?) depending of the local charge rates.

- + 5 pcs. of 12 GPM in One chamber as standby units @ 15 watts = total of 75 watts

- + 6 units of 12 GPM as UV Ozone discharge @ 15 watts = total of 90 Watts

- 2. chemicals - Chemical Oxygen demand

- - Not necessary for Biological Oxygen Demand (BOD) but maybe, as the need requires

- - for Biological Oxygen Demand (BOD)

- - 1 sack of dog food a year at 1500 to 2500 per sack depends on Brand

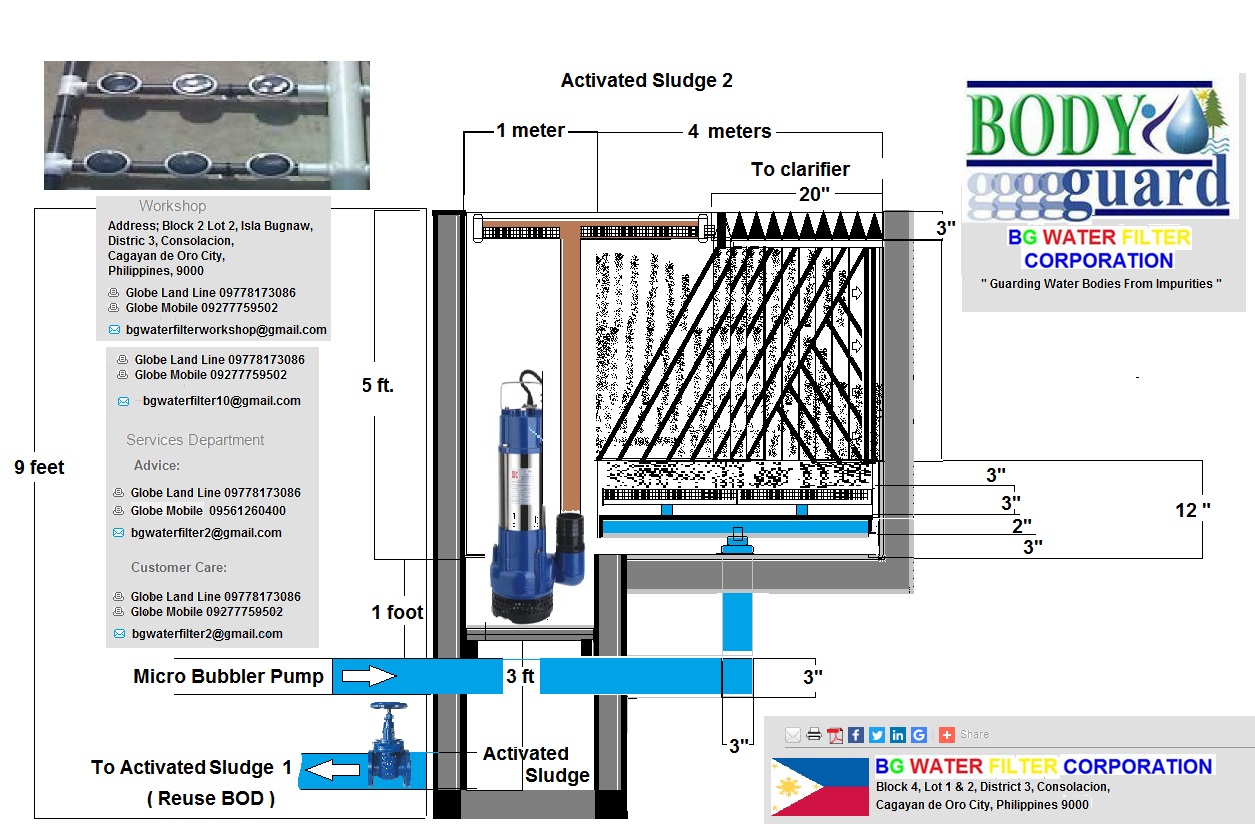

- - Micro Bubbler Pump. 1 pc. - Pls. refer to Micro Bubbler Pump Specification

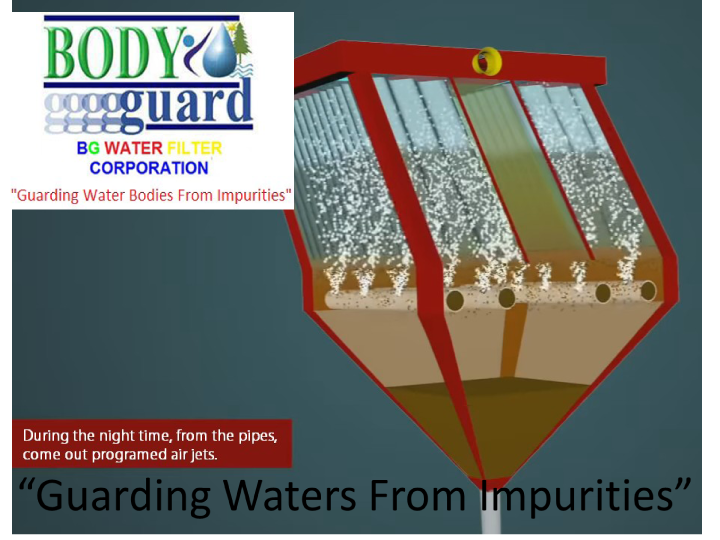

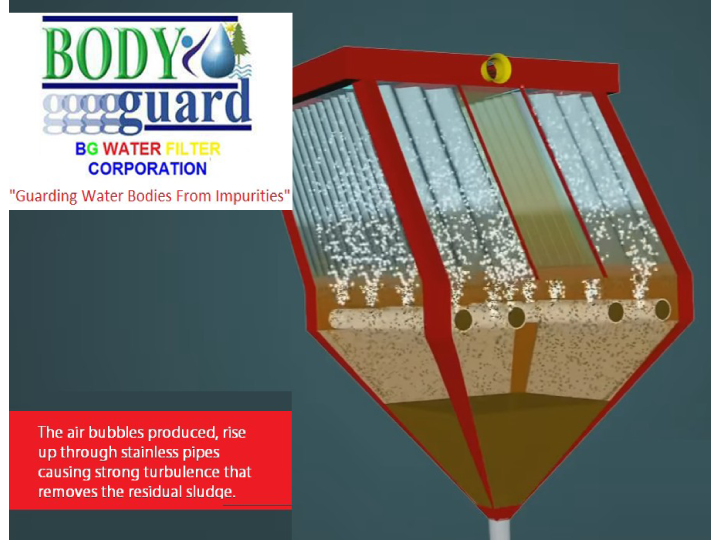

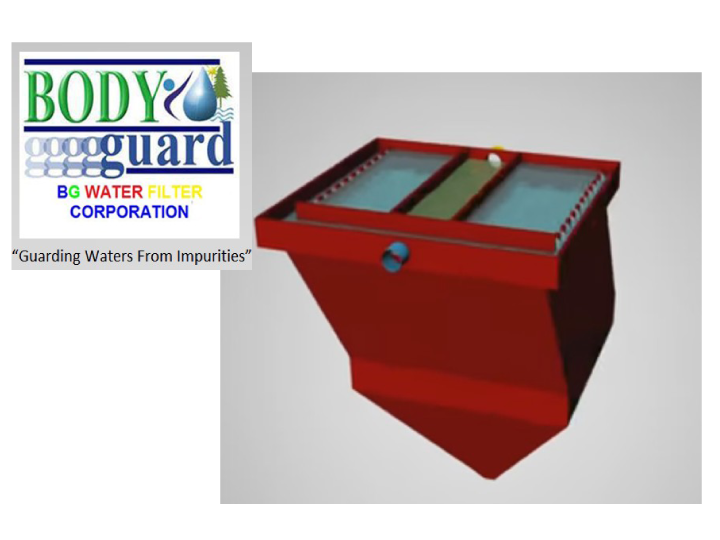

- 3. maintenance & repairs - with BG's Water Tech, the system just needs rough time, cleaning

- - once a year as far as maintenance cost are concerned.

- - Weekly inspection through a transparent glass.

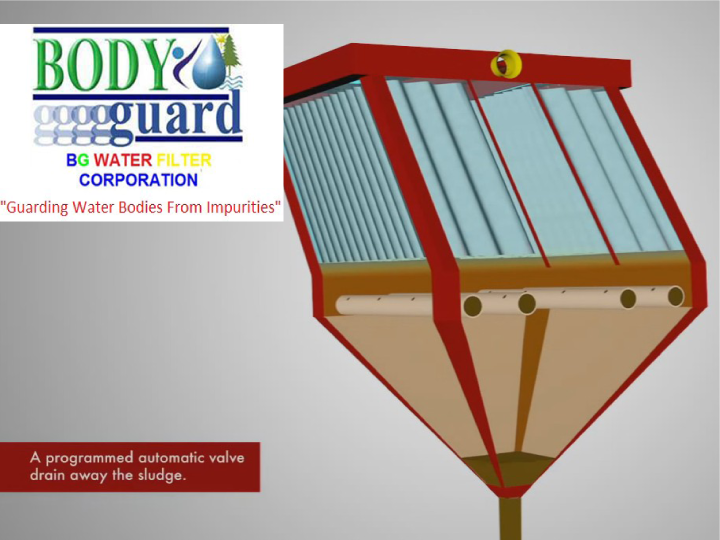

- 4. sludge handling

Secondary treatment system has to serve or pumped out 2 or 4 times each year and it costs thousands of pesos each time. That's a hidden cost of the other systems that industrial companies need to know about, but with BG's Water Tech our tanks onlyl need pumping once every 6 years for 50, 000 liters a day to 12 years depending on how much waste water are being processed.

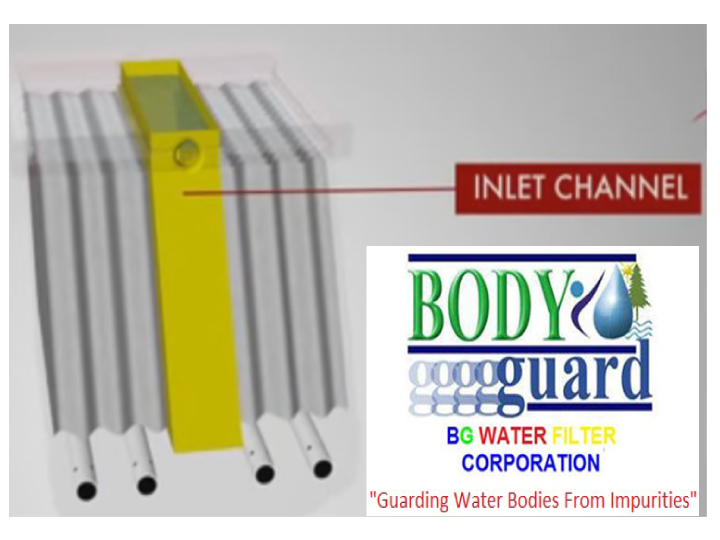

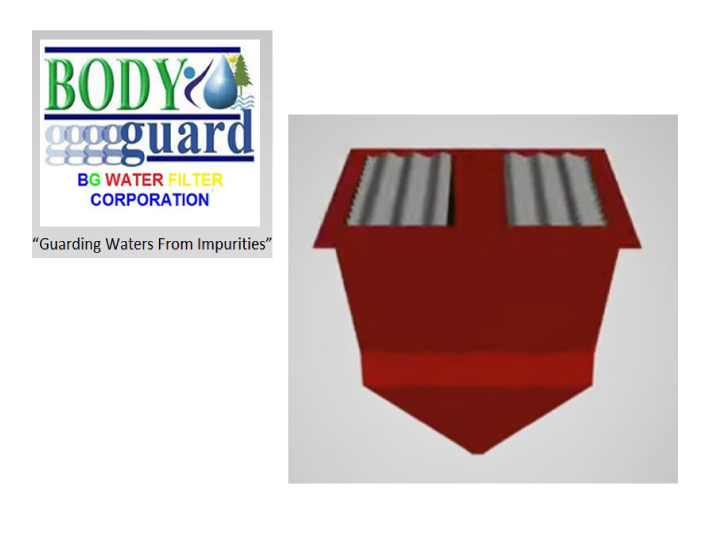

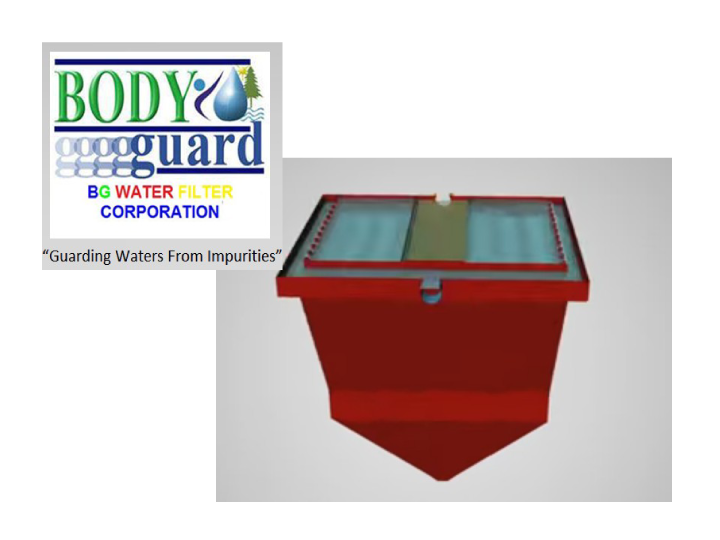

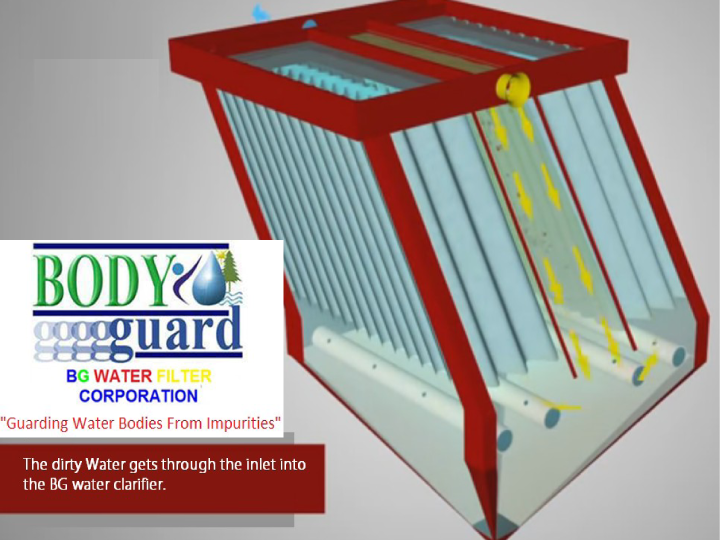

Its chamber’s cover are equipped with a thick transparent glass in order to see what is going on inside the chamber as well as installed electric valve that will serve as the light inside the chamber during inspection/observation.

Engr. FRANCISCO M. BAX

Chemical Engr. Consultant

Product Specialization

Food and Beverage Industry, Fresh Fruits Operation, Meat and Poultry Processing, Water and Waste Water Treatment Systems Bottle washing and Conveyor Lubrication in automatic dosing system, Bottle washing operation and control procedures, filling and pasteurization. Process equipment design, facilitate revisions and improvements

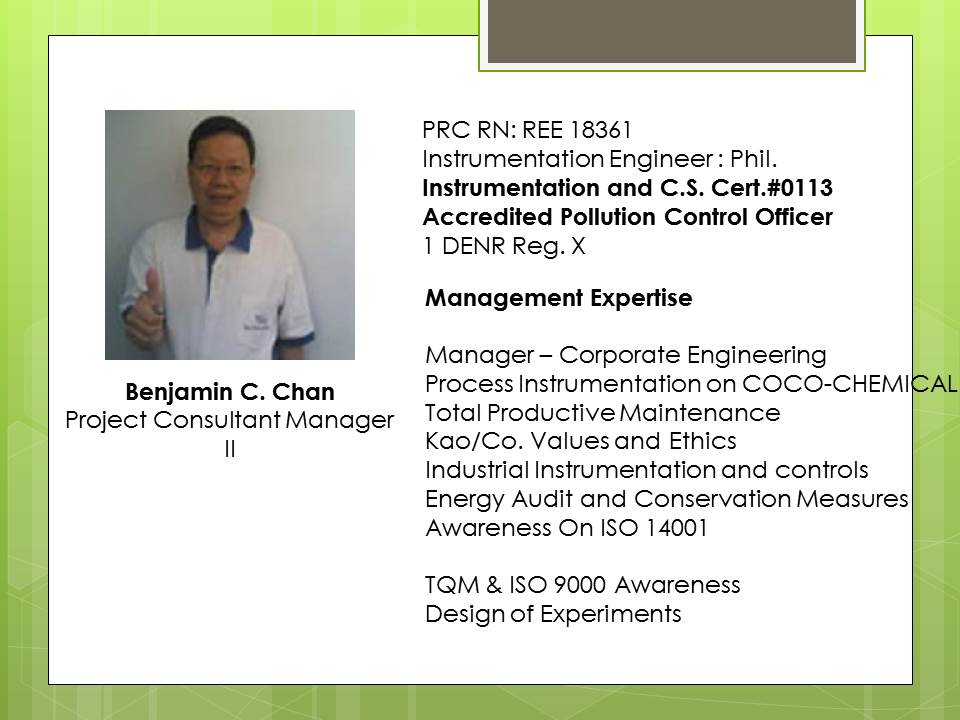

Darry Blancaflor Junsay

Mechanical Engineer Consultant

Project Engineer

In charge in the design and Supervision of Outdoor,Projects for the Company.

Lend technical assistance to the Sales marketing in the field.

Estimates and Prepare quotation for the proposed various projects.

Design, fabricate and supervise the construction, Supervise the contracted repair and maintenance for KENRAM inc. at Isulan, Sultan Kudarat.

ozone water microbubble pump, gas liquid mixing pump, water pump

Mixing system for ozone dissolved in water

- Mixing system is simple and it intakes Ozone gas to the pump and mix Ozone with liquid in the pump, while conventional system needs additional equipment like "ejector" and "static mixer" to make ozone water.

- Ozone dissolution ration is more than 80 ~ 100% in case of out mixing system which is extremely high compared with conventional system. This dissolution ratio varies depending on water temperature, gas concentration, PH concentration etc.

- CH Mixing pump is most suitable to pressurize the air and liquid, and let the air dissolved into the liquid, compared with any other type of pumps and apparatus like atatic mixer.

- CH system does not use compressor, pressure dissolve tank, ejector and static mixer, which makes our system small in size and competitive in price. In case of conventional centrifugal pump method, the pump suck the liquid and air, and mix them and transport them.

Features

Stable performance, High efficiency, Low noise, Simple in instruction and operation

Working condition

* GO and GOL designed for clear and low viscosity liquid, or liquid containing extra-fine foreign matters.

* Liquid temperature: -150C ~ 1200C

* Maximum ambient temperature: +400C

* Gas-liquid ratio 1:9 (Gas suction volume 8 ~ 10%)

* Inlet: horizontal, Outlet: Vertical

Parameters

| Item | 20QY-1 | 25QY-2 | 40QY-6 | 50QY-12 |

| Head of delivery | 40 | 50 | ||

| Flow rate M3/Hr | 0.4 ~ 2.8 | 1 ~ 3.5 | 3.5 ~ 8 | 7.5 ~ 18 |

| Water input size (Inch) | 0.75" | 1" | 1.5" | 2" |

| Water output size (Inch) | 0.5" | 0.75" | 1.2" | 1.5" |

| Power (Kw) | 0.55 | 1.1 | 3 | 5.5 |

| Phase | Single | Single | Triphase | Triphase |

| Voltage | 220V/50Hz | 220V/50Hz | 380V/50Hz | 380V/50Hz |

| Speed (r/min) | 2900 | |||

BG Series

Features:

A. Quartz glass tube, corona discharge technology

B. High grade stainless steel 304 housing, atmospheric and beautiful, durable.

C. Air & water cooled, long service life.

D. High conversion efficiency, low energy consumption

E. Compatible with air or external oxygen source.

F. Air compressor integrated, Adjustable ozone output

Specifications:

| Input voltage V/Hz | 220 - 240 / 50 - 60Hz |

| PowerW | ≤ 1140 |

| Ozone density Mg/L | 15 - 25 |

| Outlet diameter MM | 8 |

| Ozone output G/Hr | 100 |

| Size MM | 550 * 450 * 1230 |

| NW Kg | 75 |

| Housing | Stainless steel 304 |

Applications

1. Keep fruits and vegetables fresh in cold room, ozone for grain, seed disinfection

2. Remove smell and odor of sea food factory, slaughtering, poultry and kill bacteria

3. Disinfect production water supply, disinfect water for poultry feeding.

4. Surface sanitation, swimming pool and SPA, aquaculture and aquarium water sterilization.

5. Cosmetic, mushroom, food processing and storage, pharmaceutical workshop, cooling tower

But these aren’t the only reasons to place your trust in WaterTech equipment of BG Water treatment corp. WaterTech isn’t just a product it’s a comprehensive program all WaterTech system are sold only to BG Water Filter Corp by trained and Authorized BG Technicians, installed by trained authorized installers and maintained by trained and authorized service providers and these installers and service providers had discovered that WaterTech and BG Water Filter Corp. offers them benefits too.

Major Resupplier Re:

BG-WFC and WaterTech Philippines, goal was to create a high quality maintenance system withtout sacrificing performance, with BG's WaterTech, the system just needs rough time, cleaning and inspection once a year as far as maintenance cost are concerned.

Management Profile